In many production environments, picking and stacking pallets is still a manual task or one is dependent on a colleague with forklift certification. This takes a lot of time unnoticed and causes regularly delays and frustrations in the process, in addition to the unnecessary risks in terms of safety for employees and forklifts on the shop floor that can quite often cause damage.

An Automatic Pallet Dispenser, such as the Silverline, solves this easily:

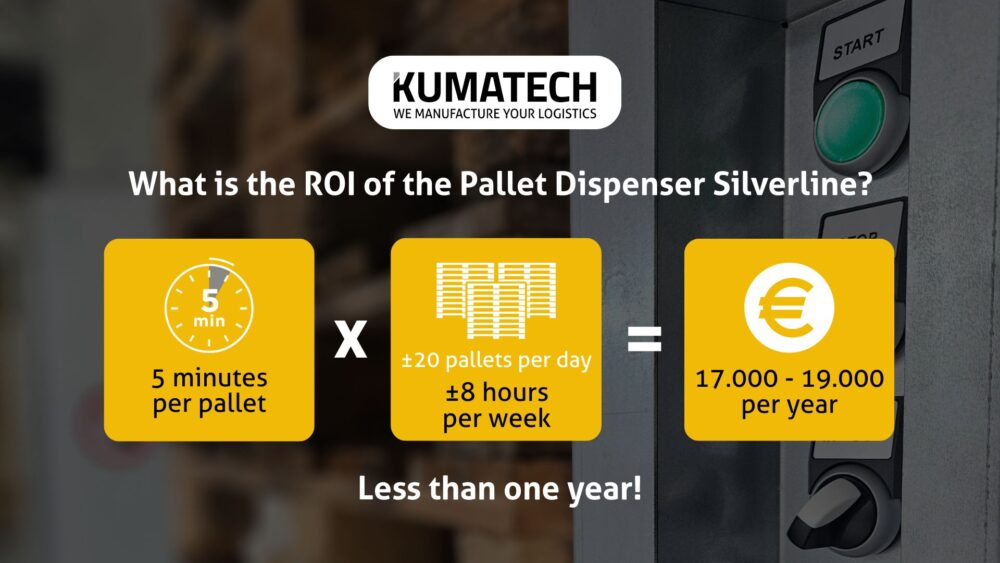

You quickly save 5 minutes per pallet with a Pallet Dispenser. If an employee picks up an average of 20 pallets per day, that’s already more than 1,5 hours per day and the time savings quickly add up. On a weekly basis, that adds up to more than 8 hours, or 32 hours per month.

If we calculate with a conservative hourly cost of € 45,- per employee, this results in savings of € 1.440,- per month. So within 1 year, the investment in a Pallet Dispenser will be recouped – and that’s not even counting the additional gains in space, safety and job satisfaction.

Lack of space? That’s also expensive

Is there no space within the company for a dispenser? Ironically, this is often due to inefficient use of space. Pallets are scattered around, stored outside or blocking walking routes. This often sounds like a quick solution, but it actually takes extra time to retrieve them and creates more frustrations and risks.

With a Pallet Dispenser you create one fixed location for pallets – organized, safe and immediately accessible. Not only you save time, but you also work more cleanly and safely. A clear process, for everyone, ensures peace of mind and maximum efficiency.

Conclusion

The Pallet Dispenser creates a neat, orderly and safe working environment. Because pallets are stacked or dispensed automatically and in a fixed place, lifting or manually picking up heavy pallets is no longer necessary. This significantly reduces the risk of injuries or accidents. Moreover, a forklift is no longer needed, further reducing the risk of damage and dangerous situations on the shop floor. This not only contributes to increased efficiency, but also to increases job satisfaction. And with a realistic payback period of only 1 year, the investment is quickly justified.